|

7/16/2023 0 Comments Announcing ISO 13485 Certification SAN JOSE, Calif., July 14, 2023 -- Cephasonics, a leader in AI-enabled OEM ultrasound platforms and development systems, today announced that it has received ISO 13485:2016 certification. Cephasonics recently completed its ISO 13485 audit and has received certification from American Systems Registrar that its quality management system for engineering and design as well as manufacturing have met the ISO13485 requirements. (American Systems Registrar (ASR) is an ANAB accredited and IATF approved registrar.) Randall Whiting, Chief Operating Officer of Cephasonics, stated, “The receipt of the ISO certification helps validate our strong commitment to quality through out device, manufacturing and customer support areas. Notably, this ISO certification marks the continuation and acceleration of our commitment to providing best-in-class OEM platforms for developing next generation medical ultrasound systems that support our customers' requirements.” ISO 13485:2016 an internationally recognized quality standard that is intended to ensure that medical devices and related services have consistent design, development, production, and sale of products that are fit for purpose as per intended use. To be certified, organizations must demonstrate that their Quality Management Systems are able to provide products and related services that consistently meet customer and applicable regulatory requirements. Cephasonics is a worldwide OEM supplier of precision real-time ultrasound systems that help companies and researchers design, develop and produce next generation clinical ultrasound imaging products and solutions. Cephasonics is ; advancing ultrasound with AI-enabled real-time data-driven capabilities that enable ultrasound to be used in a myriad of new ways from assisting medical robotics, to providing real-time data to doctors and surgeons, all without the need for trained specialists.

0 Comments

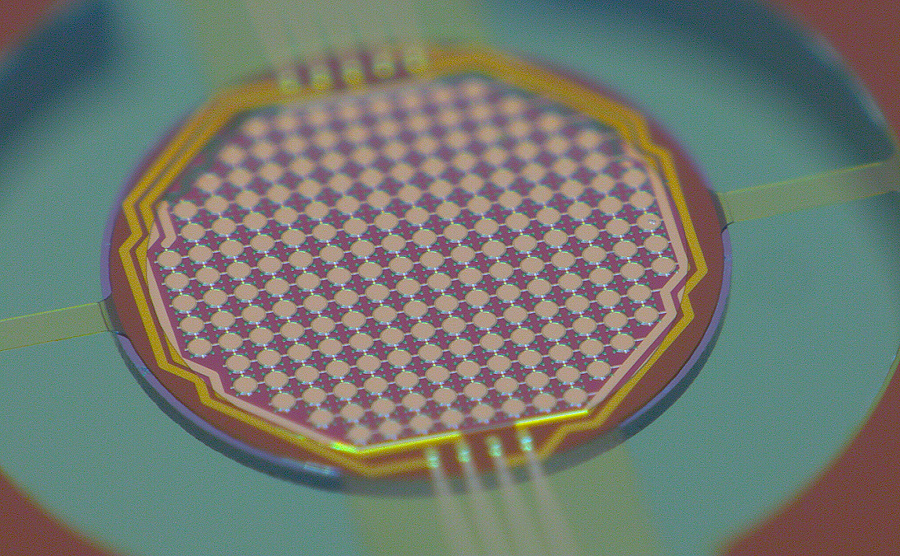

6/10/2022 2 Comments June 10th, 2022Cephasonics Ultrasound and the Philips MEMS Foundry announced a relationship to collaborate on expanding the market for Philips CMUT devices and expand support for development of new CMUT ultrasound applications. Through this relationship, Cephasonics and the Philips MEMS Foundry will jointly develop and implement programs to make it easier for developers to evaluate CMUT technology as well as build new CMUT-based applications with an out-of-the-box development solution.

As part of the collaboration, Cephasonics Ultrasound and Philips MEMS Foundry are bundling a complete CMUT-ready ultrasound development platform based on the Cephasonics ultrasound system and the Philips CMUT devises that can be used to evaluate and build next generation commercial CMUT ultrasound applications more quickly. This is generally not feasible with traditional ultrasound systems since application developers can face significant challenges integrating all the right system components before they can even begin working on new application concepts. This collaboration between Cephasonics Ultrasound and the Philips MEMS Foundry will reduce the barriers and time frame for developers to begin creating new CMUT applications. According to Paul Bekkers, business development manager for CMUT devices at Philips MEMS Foundry, “CMUT devices represent a significant new market opportunity to develop lower cost and higher performance ultrasound systems and that the new CMUT support from Cephasonics will help provide a complete CMUT ultrasound development platform making it easier for developers to create new CMUT-based solutions.” Randall Whiting, VP at Cephasonics said “We’re very excited about working with the Philips MEMS Foundry on both programs to promote CMUTs as well as integrating Philips CMUT devices with the Cephasonics ultrasound platform. We believe the relationship between Philips MEMS Foundry and Cephasonics will provide the quickest way to develop and commercialize new CMUT-based ultrasound systems in the market.” CMUTs – capacitive micromachined ultrasonic transducers – is a breakthrough ultrasound technology. CMUT transducers are MEMS based structures that can be used to transmit and receive acoustic signals in the ultrasonic range. CMUTs enable breakthrough applications for ultrasound technology in a diverse range of industries such as medical, microscopy, inkjet printing and testing among others. Compared to conventional technology, CMUT ultrasound transducers convey numerous advantages such as large bandwidth, easy fabrication of large arrays, and integration with driver circuitry: CMUT-on-CMOS. Philips’ CMUT technology enables high volume ultrasound transducer manufacturing and high levels of integration at a lower cost. Their CMUT technology platform shortens design cycles and therefore your time-to-market. The relationship between the Philips MEMS Foundry and Cephasonics will provide the quickest way to develop and commercialize new CMUT-based ultrasound solutions. Cephasonics’ ultrasound technology provides a wide range of ultrasound engines with high performance and low noise designed for product development, OEM and research applications. Cephasonics’ open architecture and flexible embedded-ultrasound provides unique access to comprehensive scanning data for AI applications. They also provide open development tools that empowers customers to quickly create and commercialize innovative new ultrasound applications. Cephasonics is creating new approaches to how and where ultrasound can be used based on expanded real-time access to data. About Philips MEMS Foundry: The Philips MEMs Foundry, a part of Philips Engineering Solutions, designs, develops, and manufactures custom microelectromechanical systems (MEMS) and assembles micro devices. Their 140 experts working at the MEMS Foundry and Micro Devices Facility follow a phase-gated approach to demonstrate the feasibility and give proof of concept, develop the process to the required maturity level and manufacture your devices with the right quality. Find more information on the Philips CMUT solutions at https://www.engineeringsolutions.philips.com/cmut 6/10/2022 0 Comments CMUT Development support Cephasonics Ultrasound and Philips MEMS Foundry Team Up to Support CMUT Application Development Cephasonics Ultrasound and the Philips MEMS Foundry announced a relationship to collaborate on expanding the market for Philips CMUT devices and expand support for development of new CMUT ultrasound applications. Through this relationship, Cephasonics and the Philips MEMS Foundry will jointly develop and implement programs to make it easier for developers to evaluate CMUT technology as well as build new CMUT-based applications with an out-of-the-box development solution. As part of the collaboration, Cephasonics Ultrasound and Philips MEMS Foundry are bundling a complete CMUT-ready ultrasound development platform based on the Cephasonics ultrasound system and the Philips CMUT devises that can be used to evaluate and build next generation commercial CMUT ultrasound applications more quickly. This is generally not feasible with traditional ultrasound systems since application developers can face significant challenges integrating all the right system components before they can even begin working on new application concepts. This collaboration between Cephasonics Ultrasound and the Philips MEMS Foundry will reduce the barriers and time frame for developers to begin creating new CMUT applications. According to Paul Bekkers, business development manager for CMUT devices at Philips MEMS Foundry, “CMUT devices represent a significant new market opportunity to develop lower cost and higher performance ultrasound systems and that the new CMUT support from Cephasonics will help provide a complete CMUT ultrasound development platform making it easier for developers to create new CMUT-based solutions.” Randall Whiting, VP at Cephasonics said “We’re very excited about working with the Philips MEMS Foundry on both programs to promote CMUTs as well as integrating Philips CMUT devices with the Cephasonics ultrasound platform. We believe the relationship between Philips MEMS Foundry and Cephasonics will provide the quickest way to develop and commercialize new CMUT-based ultrasound systems in the market.” CMUTs – capacitive micromachined ultrasonic transducers – is a breakthrough ultrasound technology. CMUT transducers are MEMS based structures that can be used to transmit and receive acoustic signals in the ultrasonic range. CMUTs enable breakthrough applications for ultrasound technology in a diverse range of industries such as medical, microscopy, inkjet printing and testing among others. Compared to conventional technology, CMUT ultrasound transducers convey numerous advantages such as large bandwidth, easy fabrication of large arrays, and integration with driver circuitry: CMUT-on-CMOS. Philips’ CMUT technology enables high volume ultrasound transducer manufacturing and high levels of integration at a lower cost. Their CMUT technology platform shortens design cycles and therefore your time-to-market. The relationship between the Philips MEMS Foundry and Cephasonics will provide the quickest way to develop and commercialize new CMUT-based ultrasound solutions. Cephasonics’ ultrasound technology provides a wide range of ultrasound engines with high performance and low noise designed for product development, OEM and research applications. Cephasonics’ open architecture and flexible embedded-ultrasound provides unique access to comprehensive scanning data for AI applications. They also provide open development tools that empowers customers to quickly create and commercialize innovative new ultrasound applications. Cephasonics is creating new approaches to how and where ultrasound can be used based on expanded real-time access to data. About Cephasonics: Cephasonics Ultrasound is a worldwide supplier of precision real-time ultrasound systems for product development and embedded OEM ultrasound applications. Cephasonics’ technology powers innovation in the design and development of next-generation ultrasound medical and industrial ultrasound imaging solutions. Cephasonics Ultrasound also provides custom engineering and design services for the development of new ultrasound hardware, AI applications, probes, and complete ultrasound systems. For more information on Cephasonics Ultrasound technology and products: www.cephasonics.com About Philips MEMS Foundry: The Philips MEMs Foundry, a part of Philips Engineering Solutions, designs, develops, and manufactures custom microelectromechanical systems (MEMS) and assembles micro devices. Their 140 experts working at the MEMS Foundry and Micro Devices Facility follow a phase-gated approach to demonstrate the feasibility and give proof of concept, develop the process to the required maturity level and manufacture your devices with the right quality. Find more information on the Philips CMUT solutions at https://www.engineeringsolutions.philips.com/cmut

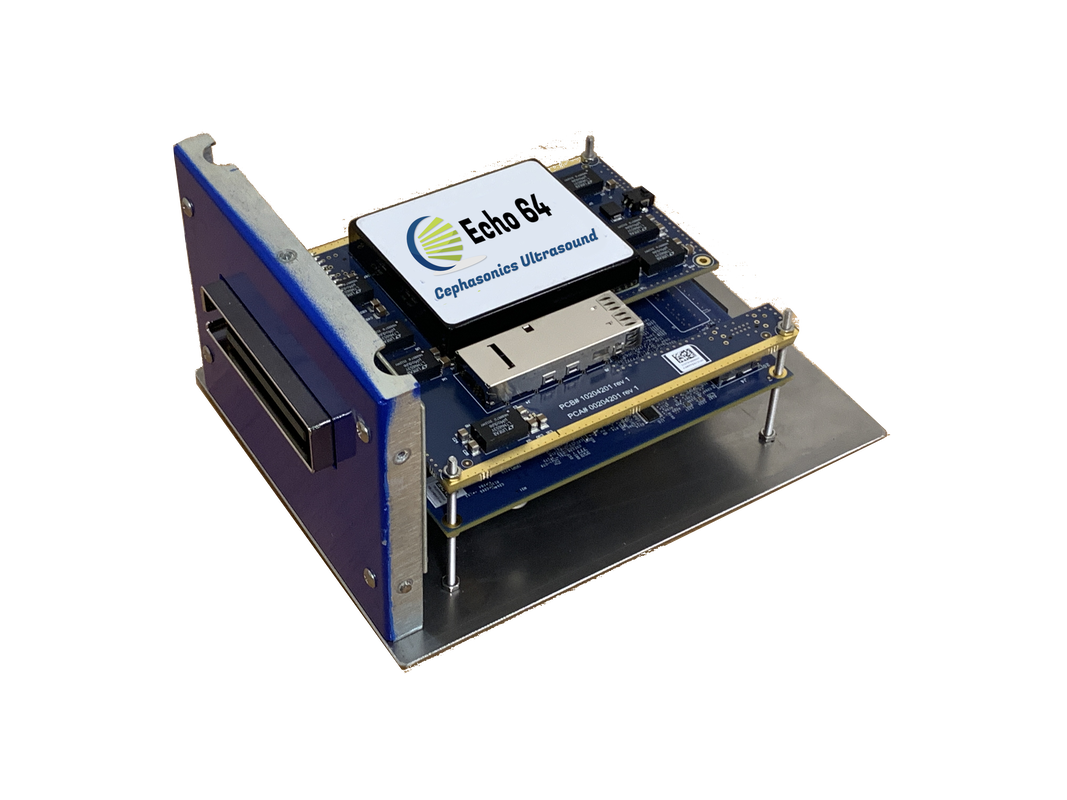

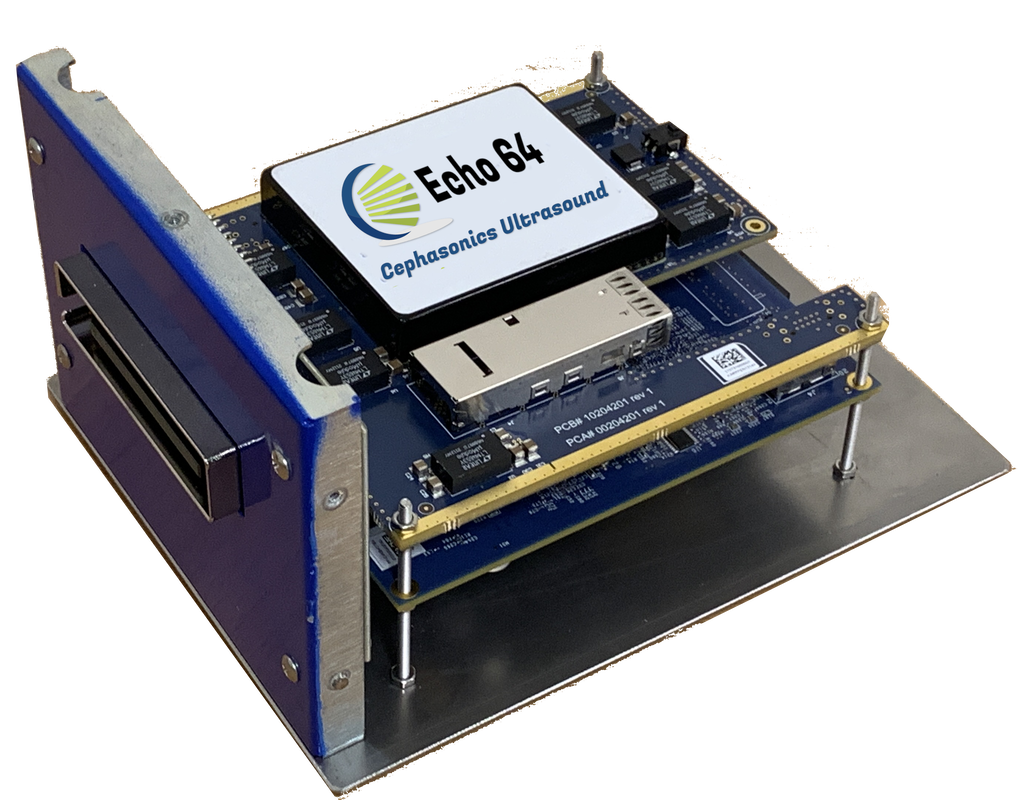

The Echo-64 is designed to be used in OEM applications to power new ultrasound systems or integrate ultrasound into preexisting CAP (computer-added medical procedures) products and systems. Based on Cephasonics’ Itasca architecture, the Echo board-level systems provide the ability to custom design and build full-featured ultrasound systems that offer a high-level of flexibility, small footprint, and excellent image quality, thus enabling fast time-to-market for development and integration of new ultrasound capabilities.

Cephasonics founder and CEO, Richard Tobias stated, “Integrating ultrasound into other medical systems used in various procedures can dramatically enhance the effectiveness of computer-aided medical procedures by adding real-time ultrasound-based measurement capabilities. Our Echo 64 systems will make it easier to design and commercialize new innovations in how ultrasound can be integrated into supporting real-time medical procedures.” Cephasonics’ Itasca architecture represents a new approach to designing ultrasound systems where more processing power utilizing FPGAs is located closer to the source of the data. This enables an ultrasound system to process more complex algorithms in real-time avoiding data bottlenecks in transferring data to a connected computer. This architectural approach allows for accessing and utilizing much greater amounts of data in real time enabling new applications of ultrasound that cannot be accomplished by traditional ultrasound systems. This design paves the way for the development of much higher performance systems perfect for AI and quantitative measurements. According to Dr. Jeremy Dahl, an ultrasound researcher and Associate Professor of Radiology at Stanford University's School of Medicine., "Architectures like Itasca that can move computational power closer to the source of the ultrasound data will help make new approaches such as software beamforming a commercial reality. These types of technologies will be critical to the future of diagnostic ultrasound imaging because they enable novel imaging applications to be utilized for the betterment of patient care.” Specifications: The Echo-64 system utilizes Cephasonics’ new high-speed fiber computer interface, iCUF-Link, which is able to sustain data rates supporting 64-channels continuously at 50 M samples / second in real-time to a connected PC. The system supports transmit output pulse rates from 100Hz to 50MHz as well as 5ns delay resolution. On the receive side, the Echo 64 system features a 12-bit ADC with an ultra-low 2.4dB noise figure. It will support input frequencies from 1MHz to 20MHz and sampling rates of 20MHz and 50MHz. The new Echo-64 system operates with APIs from the Cephasonics software development environment, CuSDK. CuSDK enables medical product companies as well as researchers to easily develop new AI and real-time quantitative ultrasound applications with a Cephasonics Cicada development system. The Echo- 64 systems will also offer options for add-on power supply and probe interface adapters. Lastly, with the Echo-64 design, Cephasonics can also create implementations of higher channel- count or specialized application board-level ultrasound solutions for custom applications of ultrasound including transmit only/receive only implementations. Pricing & Availability: The Echo-64 kit will be available to order starting in Q2 2022 and be priced in single unit quantities at $15K/kit. 12/24/2021 0 Comments Cephasonics announces echo-64Cephasonics Announces a complete 64-channel ultrasound system delivered on 2 small-format circuit boards that sets new standard for ability to integrate/build small-format high-performance ultrasound systems Today, Cephasonics announced Echo-64, . The Echo-64 is designed to be used in OEM applications to power new ultrasound systems or integrate ultrasound into preexisting CAP (computer-added medical procedures) products and systems. Based on Cephasonics’ Itasca architecture, the Echo board-level systems provide the ability to custom design and build full-featured ultrasound systems that offer a high-level of flexibility, small footprint, and excellent image quality, thus enabling fast time-to-market for development and integration of new ultrasound capabilities.

Cephasonics founder and CEO, Richard Tobias stated, “Integrating ultrasound into other medical systems used in various procedures can dramatically enhance the effectiveness of computer-aided medical procedures by adding real-time ultrasound-based measurement capabilities. Our Echo 64 systems will make it easier to design and commercialize new innovations in how ultrasound can be integrated into supporting real-time medical procedures.” Cephasonics’ Itasca architecture represents a new approach to designing ultrasound systems where more processing power utilizing FPGAs is located closer to the source of the data. This enables an ultrasound system to process more complex algorithms in real-time avoiding data bottlenecks in transferring data to a connected computer. This architectural approach allows for accessing and utilizing much greater amounts of data in real time enabling new applications of ultrasound that cannot be accomplished by traditional ultrasound systems. This design paves the way for the development of much higher performance systems perfect for AI and quantitative measurements. According to Dr. Jeremy Dahl, an ultrasound researcher and Associate Professor of Radiology at Stanford University's School of Medicine., "Architectures like Itasca that can move computational power closer to the source of the ultrasound data will help make new approaches such as software beamforming a commercial reality. These types of technologies will be critical to the future of diagnostic ultrasound imaging because they enable novel imaging applications to be utilized for the betterment of patient care.” Specifications: The Echo-64 ultrasound system features a dual-board configuration that provides 64 transmit and receive channels with 3 levels of pulsing. It also supports real-time streaming and plane wave imaging eliminating many of the constraints of traditional beam-forming ultrasound. The system is made up of 2 interconnected circuit boards that measure approximately 4”W X 5”D x 3”H. The Echo-64 system utilizes Cephasonics’ new high-speed fiber computer interface, iCUF-Link, which is able to sustain data rates supporting 64-channels continuously at 50 M samples / second in real-time to a connected PC. The system supports transmit output pulse rates from 100Hz to 50MHz as well as 5ns delay resolution. On the receive side, the Echo 64 system features a 12-bit ADC with an ultra-low 2.4dB noise figure. It will support input frequencies from 1MHz to 20MHz and sampling rates of 20MHz and 50MHz. The new Echo-64 system operates with APIs from the Cephasonics software development environment, CuSDK. CuSDK enables medical product companies as well as researchers to easily develop new AI and real-time quantitative ultrasound applications with a Cephasonics Cicada development system and then easily port them to new Echo-based ultrasound systems. The Echo-64 systems will also offer options for add-on power supply and probe interface adapters. Lastly, with the Echo-64 design, Cephasonics can also create implementations of higher channel-count or specialized application board-level ultrasound solutions for custom applications of ultrasound including transmit only/receive only implementations. Pricing & Availability: The Echo-64 kit will be available to order starting in Q2 2022 and be priced in single unit quantities at $15K/kit. 10/27/2021 2 Comments New vision-based robotic 3D ultrasoundTechnical University of Munich developed in conjunction with Zhejiang University and Johns Hopkins University a new vision-based robotic 3D ultrasound system powered by Cephasonics to create accurate 3D scans even if the target limb changes position after the scan begins.

While 2D ultrasound imaging can provide images in real time even if the target moves, 3D ultrasound imaging is much more sensitive to changes in movement. Repositioning limbs, for example, may be necessary to make different parts of a limb available to the ultrasound probe in order to image an entire artery. The angle of the 2D image changes from its original position, making it difficult to stitch the images together into a 3D representation. Robotic ultrasound systems (RUSS) produce high quality images by precisely controlling the contact force and orientation of the ultrasound probe. Combining robot arms with depth cameras to determine optimal probe position increases the accuracy of the scan. This is still not effective for 3D imaging because this system also cannot account for movement of the scan target. The new system developed by the researchers, as described in the paper titled “Motion-Aware Robotic 3D Ultrasound” (bit.ly/VSD-MTN3D), combines RUSS with depth cameras to make 3D imaging with ultrasound possible. The system uses a LBR iiwa 14 R820 robot arm from Kuka (Augsburg, Germany; www.kuka.com/en-us), a Cicada LX ultrasound machine from Cephasonics Ultrasound (Santa Clara, CA, USA; www.cephasonics.com), and an Azure Kinect 3D camera from Microsoft (Redmond, WA, USA; www.microsoft.com/en-us). The process begins by drawing a red line on the patient’s skin to mark the path of the ultrasonic probe during the scan. The Kinect camera images the line, and the software registers the path to calculate a trajectory for the robot arm. Two marker spheres with retroreflective layers are placed on both ends of the drawn red line. The spheres help provide reliable position data for the Kinect camera and aid in extracting region of interest and trajectory data. This helps the system account for limb position adjustment during the scan. Because the system can assign 3D coordinates to images during the scan, even if the limb moves, the system can compensate for the movement and stitch the images together as if the limb movement never took place. This allows for creating accurate 3D scan data. Testing demonstrated that the system compensates for up to 40° of target rotation. The researchers proposed that a laser system could project a trajectory onto the surface of a limb and replace the drawn red line. Also, while the system test simulated vascular scans, the system could also perform bone visualization. 4/13/2021 1 Comment Cephasonics at LSI Medtech SummitCephasonics selected as an Innovation Leader at the LSI 2021 Emerging Medtech Summit.  We're very excited about being a part of the upcoming LSI Emerging MedTech Summit (in person) and to be recognized as an innovation leader in our industry. We'll be presenting a new approach to using ultrasound in clinical applications for non-invasive somatic measurements using AI, and ultrasound data. We will present how Cephasonics' ultrasound technology is enabling applications & products to automatically recognize, locate, and measure things in the body in real-time. Our approach is designed to deliver more precise and usable data as a tool in medical procedures, add new capabilities to medical devices and robotics and expand the use of ultrasound in quantitative diagnostics especially in telehealth applications. Life Science Intelligence (LSI) is hosting the Emerging Medtech Summit May 11-13 2021 at The Ritz-Carlton in Laguna Niguel, CA. The event feature over 200 major medtech investors and selected innovators from the medtech community (both in-person and virtually) If you're planning to attend the conference, please let me know and I'd love to connect. Or, if you'd like to talk more about using ultrasound for somatic measurements in clinical applications or to augment other medtech devices with precise measurement, let us know. Contact Cephasonics For more information on the conference, please visit: www.lifesciencemarketresearch.com/medtech-summit 3/27/2020 1 Comment New Ultrasound PatentSanta Clara, CA March 15, 2020 — Cephasonics, a leader in advanced ultrasound technology and systems, today announced that the United States Patent and Trademark Office (USPTO) has issued a new patent (U.S. Patent No. 10,499,884 ) to Cephasonics Ultrasound for Ultrasound Systems and Methods for Searching for a First Object within a Second Object Using a Dynamic Hardware Scheduler Micro-controller. The invention relates to ultrasound scanning and particularly to ultrasound scanning using a plurality of beams. This expands Cephasonics patent portfolio to 8 for technology used in Cephasonics family of ultrasound development and OEM systems.

Today, most ultrasound systems have limited, fixed functionality and require sophisticated user control. Most ultrasound systems cannot provide multiple simultaneous functions. For example, an operator of a typical ultrasound system is required to be skilled in the operation of the machine and capable of directing beams to the desired bodily objects. As a result, the use of such systems is limited by available human resources. And, even in the case of a skilled person, it might prove a challenge to locate an object on or within another object. This patent covers Cephasonics technology that enables development of ultrasound systems, which can automatically find and recognize an object such as a tumor or cyst within another object such as an organ in the body without requiring an operator to be skilled in the use of the ultrasound apparatus. This patent extends 3 other patents issued to Cephasonics: A System and Method for Automatically Adjusting Beams to Scan a Desired Object in a Body”, “A Method for Scheduling Events of an Array of Ultrasound Transmitters Using a Timing Wheel”, and “A Dynamic Hardware Schedule Controller.” Cephasonics CEO, Richard Tobias commented that, “this patent advances our leadership in ultrasound AI-based applications that can locate, recognize and characterize objects within the body.” He also stated that “for our partners who are developing new ultrasound products, this also enhances our Cephasonics platform in helping them create and deliver unique value and dramatically expand where and how ultrasound can be used.” 11/2/2019 2 Comments Cephasonics Ultrasound Awarded Competitive Grant from the National Science FoundationSmall Business Innovation Research Program Provides Seed Funding for R&D Santa Clara, CA October 25, 2019 – Cephasonics Ultrasound is proud to announce that it has been awarded a National Science Foundation (NSF) Small Business Innovation Research (SBIR) grant for $225,000 to conduct research and development (R&D) toward developing a new computational architecture for AI-enabled Ultrafast Frameforming ultrasound systems (UFFFI). UFFFI is a highly effective approach to imaging and measuring conditions in the human body. However, its commercial procedure-specific usage has been impeded by the data and computational requirements for real-time processing. This research will address the computational challenges of real-time UFFFI, with the objective of creating a new computational design for an ultrasound engine able to process medical-grade image data at high frequency, enable new machine learning algorithms and support real-time clinical applications of UFFFI that can recognize, quantify and characterize structures in the body in real-time. “NSF is proud to support the technology of the future by thinking beyond incremental developments and funding the most creative, impactful ideas across all markets and areas of science and engineering,” said Andrea Belz, Division Director of the Division of Industrial Innovation and Partnerships at NSF. “With the support of our research funds, any deep technology startup or small business can guide basic science into meaningful solutions that address tremendous needs.” “We believe that by overcoming the computational challenges of UFFFI, this research will help open a new range of ultrasound applications and products that access more precise data, which will provide surgeons and doctors real time information to enhance clinical diagnosis and outcomes’” said Richard Tobias, CEO of Cephasonics. Once a small business is awarded a Phase I SBIR/STTR grant (up to $225,000), it becomes eligible to apply for a Phase II grant (up to $750,000). Small businesses with Phase II grants are eligible to receive up to $500,000 in additional matching funds with qualifying third-party investment or sales. NSF accepts Phase I proposals from small businesses year-round. Small businesses with innovative science and technology solutions, and commercial potential are encouraged to apply. All proposals submitted to the NSF SBIR/STTR program, also known as America’s Seed Fund powered by NSF, undergo a rigorous merit-based review process. To learn more about America’s Seed Fund powered by NSF, visit: https://seedfund.nsf.gov/ About the National Science Foundation's Small Business Programs: America’s Seed Fund powered by NSF awards $200 million annually to startups and small businesses, transforming scientific discovery into products and services with commercial and societal impact. Startups working across almost all areas of science and technology can receive up to $1.5 million in non-dilutive funds to support research and development (R&D), helping de-risk technology for commercial success. America’s Seed Fund is congressionally mandated through the Small Business Innovation Research (SBIR) program. The NSF is an independent federal agency with a budget of about $8.1 billion that supports fundamental research and education across all fields of science and engineering. About Cephasonics: Cephasonics is a worldwide supplier of precision real-time ultrasound systems for research, product development and embedded OEM applications. Cephasonics enables next-generation ultrasound research and development as well as enabling companies to create and commercialize new medical ultrasound imaging solutions. The Cephasonics open architecture and flexible embedded-ultrasound platform is compact, scalable to 4096 channels, and provides unique access to comprehensive scanning data for AI applications. They also provide open development tools that empower customers to quickly create and commercialize innovative new procedure-specific ultrasound applications and products that can locate, recognize, quantify and characterize structures in the body providing doctors real-time information during medical procedures. For more information, please contact:Randy Whiting (408) 772-2428 rwhiting@cephasonics.com For more information on Cephasonics: www.cephasonics.com 10/3/2019 0 Comments Working with Lambda LabsWe're very excited about the opportunity to work with Lambda Labs related to using their AI workstations combined with the Cephasonics Ultrasound engines. Lambda Labs is probably the best known producer of high-end AI workstations in the market. We're working with them to help them move into the healthcare market and at the same time be able to provide our customers a wide range of proven high-performance servers specially built for AI applications. Their performance and use of Nvidia GPUs make the Lambda Labs workstations a perfect server choice for a variety of ultrasound applications built on the Cephasonics platform.

|

Cephasonics Ultrasound is a division / registered dba of White Eagle Sonic Technologies, Inc.

Products

|

Company |

RSS Feed

RSS Feed